CNC lathing technology has come a long way since the 1950s in recent years and new developments in CNC lathing technology are making it possible to machine parts with greater accuracy, precision, and speed than ever before.

These new developments are also making CNC lathing more efficient and sustainable at Ward CNC. Contact us today to find out more on 0114 276 5411.

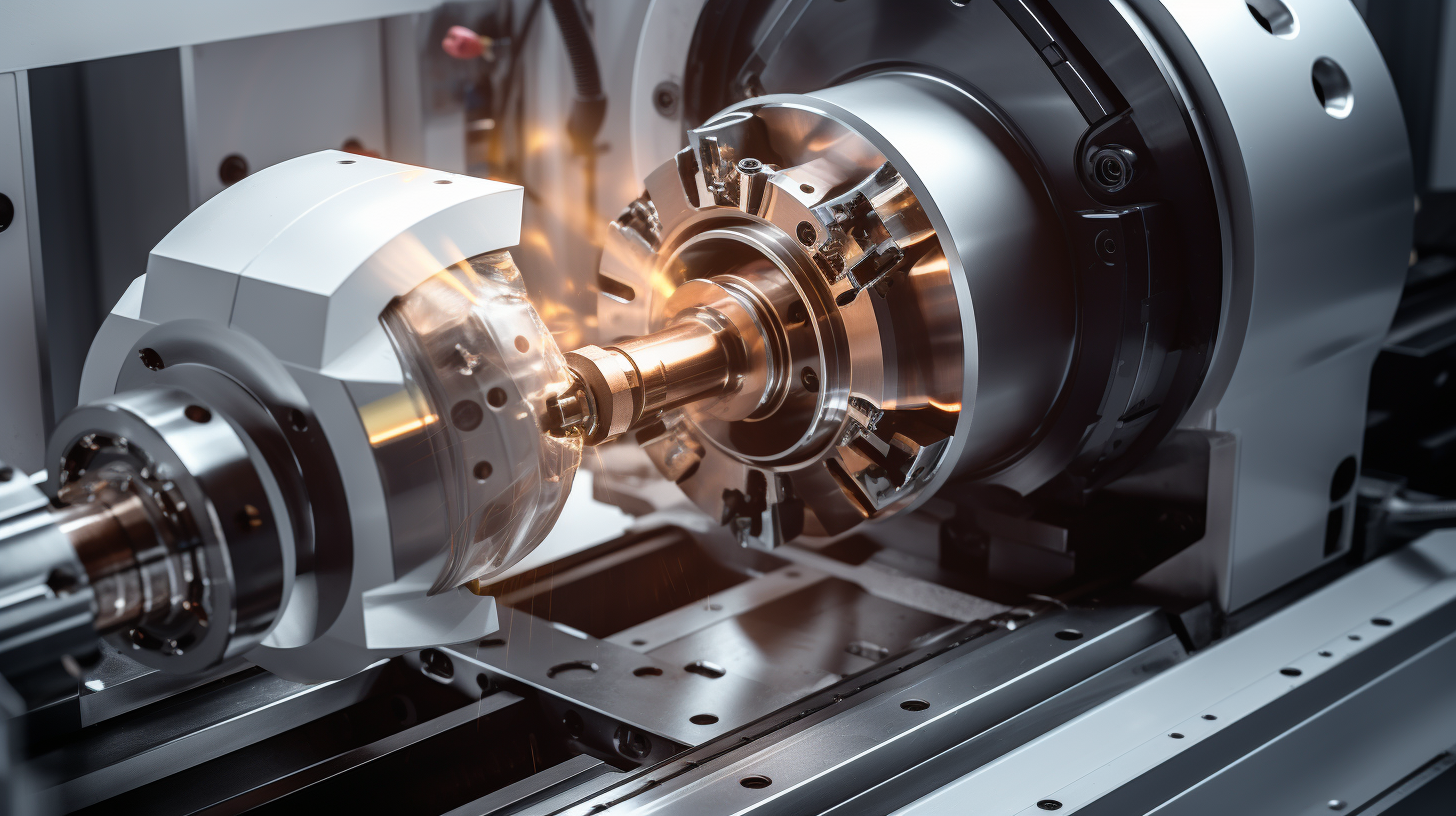

Latest developments in CNC lathing technology

As you can imagine, technology has improved dramatically over the past few decades, and this has been no different with CNC lathing technology. Let’s take a look at some of the developments that have been made within CNC lathing technology recently.

6-axis machining centres

6-axis machining centres are a type of CNC lathe that can move a workpiece in six different directions. This makes it possible to machine complex parts with intricate features without needing to re-clamp the workpiece. 6-axis machining centres are particularly well-suited for machining parts for the aerospace, medical device, and electronics industries.

High-speed machining

High-speed machining (HSM) is a machining process that uses high spindle speeds and high feed rates to remove material quickly. HSM can be used to machine a wide range of materials, including metals, plastics, and ceramics. HSM can significantly reduce machining times and improve productivity.

Tooling

New developments in tooling are also making CNC lathing more efficient and productive. There are new cutting tool materials and coatings that are making it possible to machine materials at higher speeds and feeds without sacrificing tool life. As well as this, new tool-holding systems are also making it easier to change tools quickly and accurately.

Software

CNC lathing software is also becoming more sophisticated and powerful. New software packages offer features such as simulation, optimisation, and tool path generation. These features can help manufacturers improve their machining processes and produce parts with higher accuracy and precision.

Automation

Automation is another trend that is having a major impact on CNC lathing. New automation technologies are making it possible to automate many of the tasks involved in CNC lathing, such as loading and unloading workpieces, changing tools, and measuring parts. Automation can help manufacturers improve their productivity and reduce their labour costs.

Sustainability

There has been so much talk about sustainability and the net zero initiative. Within the machining industry, sustainability is also a major concern for many manufacturers. New developments in CNC lathing technology are making it possible to machine parts in a more sustainable way.

For example, new cutting fluids and lubricants are being developed that are more environmentally friendly. New machine designs are also being developed that are more energy efficient.

How are new developments in CNC lathing technology impacting the manufacturing industry?

Because of all of the improvements in technology, there are major opportunities for the time it takes to complete a project to be brought down, which inevitably results in costs being reduced. Let’s take a look at these benefits in more detail.

- Reduced manufacturing costs – new developments in CNC lathing technology can help manufacturers reduce their manufacturing costs by increasing productivity and reducing labour costs.

- Improved product quality – new developments in CNC lathing technology can help manufacturers improve the quality of their products by producing parts with greater accuracy and precision.

- Increased competitiveness – new developments in CNC lathing technology can help manufacturers increase their competitiveness by enabling them to produce products faster and more efficiently

Overall, the technological developments in CNC lathing have made a huge impact on efficiency and productivity within manufacturing. If you are looking for the latest technology within the CNC lathing space, contact Ward CNC today!